Our means of production

The production is distributed over a total area of 2000 m2, divided into 3 main parts :

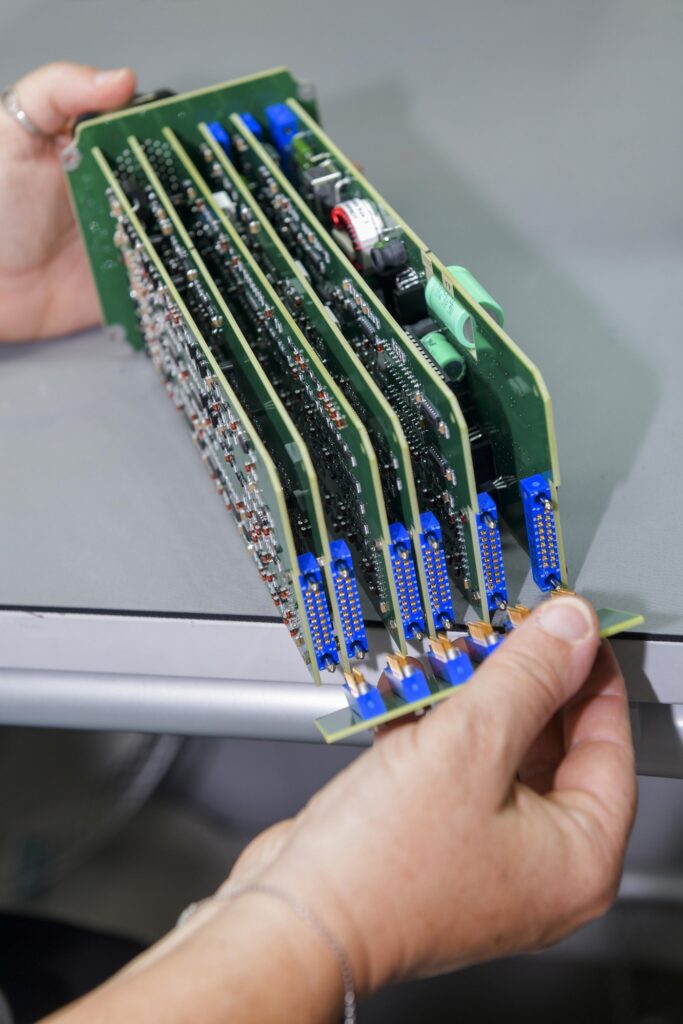

An electronic workshop

- Wire bonding

- Electromechanical assembly

- Welding and soldering

- Control and calibration

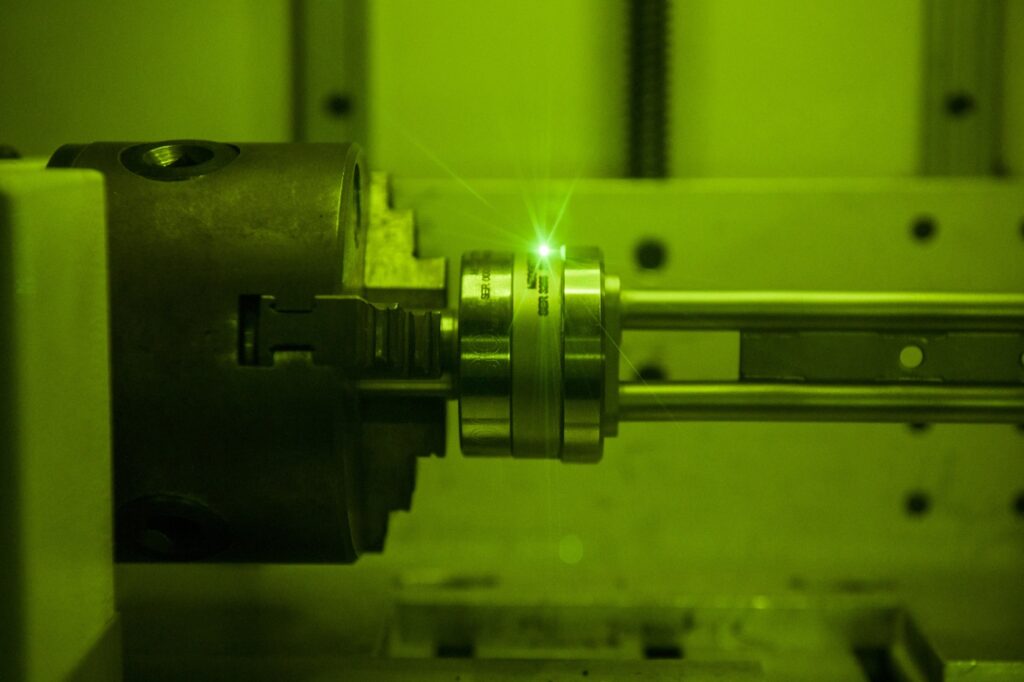

An electromechanical workshop

- Qualified welder technicians

- Semi-automatic machines

- HF solder(induction)

- Welding and manual finishing

- TIG welding

- Sandblasting

- Machining

Test equipment and qualification

- 6 climatic chambers

- 1 Halt/Hass chamber (aggravated tests)

- 1 thermal shock chamber

- 2 automatic BCU test benches

- 2 vibrating benches

- 3 sensors test benches

- Photometric benches

Our production

AEVA manufactures parts belonging to

4 families of equipment :

Turbine ignition systems

- Spark plugs

- Ignition generator

- Ignition leads

Braking Control Units

- Analog and/or FPGA electronics

- Adaptive solutions based on low consumption and high reliability

Sensors

- Speed sensors

- Pressure switches

- Thermal switches

- Thermocouples

Cockpit indicators

- Torque/Temperature (T45, AOT)

- Speed (NR, NF, NG, delta NG)

- Pressure (oil, etc…)