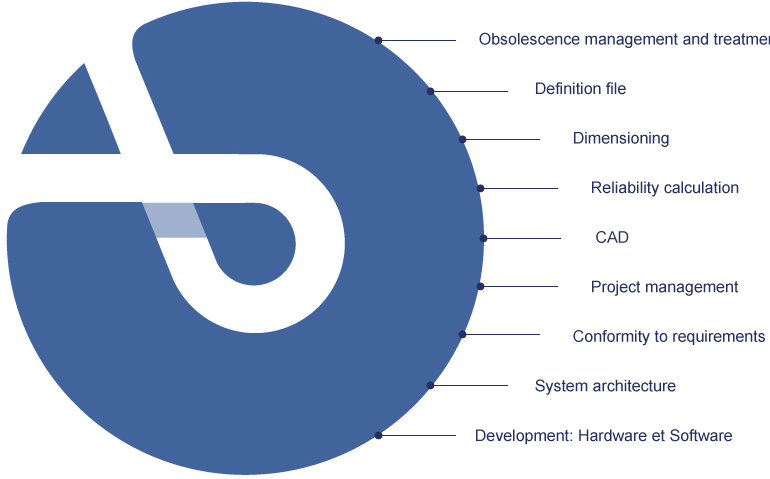

The know-how and skills of the group's teams cover the entire life-cycle of your projects.

Whether it is electronics and optics, automation and industrial information, mechanics and hydraulics, electrical engineering or LV/HV electricity, the engineers in our various design offices support their customers throughout their project.

ELECTROTECHNICS

AUTOMATION AND INDUSTRIAL IT

MECHANICS AND HYDRAULICS

HV/LV ELECTRICITY

Development plateforms

Prelimenary design

- Feasibility study

- Process study

- Analysis and Diagnosis

- Obsolescence study

Specification

- Definition of architectures

- Dimensioning

- Justification

- Preliminary design

- FMECA

- Reliability calculation

Implementation / Commissioning

- Equipment manufacturing

- Integration

- FAT/SAT and IQ, OQ, PQ qualifications

- Commissioning

- User training

- Customer services/Maintenance

Design

- Detailed design

- Development

- Modeling

- Prototyping

- Internet Service Provider

Our skills

The teams carry out development (Freescale, Intel, STM, NXP, FGPA, Xilinx, Lattice, Altera, Actel and under environments such as Linus, CMX, WE. We also matter the following protocols: CAN, CAN OPEN, CAN SAFETY, TCP/IP, Ethernet, Profibus et Wifi. Our electronic design office engineers and technicians specializes in : product architecture, electronic design (hardware & software), mechanical design, product qualification, product validation, industrialization. The design office is responsible for the following tasks : design and development of embedded systems, test and measurement equipment, recovery of “built to print” files / obsolescence treatment, product expertise / after-sales service support and et quality department.

Our teams are experienced to make your products well established, development and design rules recognised for their level of excellence (DO178 and DO254, SIL), while ensuring the required environmental standards (RTCA DO-160, MIL- STD-810, MIL-STD-704, MIL-STD-461, MIL-STD-462, EN 61000, STANAG 4236, GAM EG13, ISO 7637, AECTP 300/400, EN 2282), all reinforced by the reliability calculations (FMEA, fault catalog, fault tree, MILBDBK217F, FIDES2009, NPRD95 ..) allowing AE to be accredited by many recognised industry actors.

Involvement

- Computer-assisted proofreading

- Design

- Validation

- Qualification

- Industrialization

- Expertise

- MCO

Flexibility

- Varied customer referential

- Design from scratch or renovation

- Adaptation to customer standards

- Consideration of the specific constraints of many applications

- Rapid identification of solutions to hazards

Expertise

- REX recognised in aero-defence applications

- Co-located multi-trade team

- Control of the development cycle

- Tools and ability for customer requirements analysis

These are the major assets of the electronic design office offer

Preliminary design

- Feasibility study

- Process study

- Diagnostic

- Obsolescence study

- Functional analysis

- Technical assistance

Specification

- Definition of architectures

- Dimensioning

- Justification

- Prelimenary design

- FMECA

- Reliability calculation

Design and validation

- Detailed design

- Development

- Production and integration

- Test: qualifications (IQ, OQ)

- Start-up

- Commissioning

- Documentation

They use for this tracking tools:

- Microsoft Planning

- Documentation, configuration monitoring, quality scheme, table of requirements, risk management.

- Orders, Octal CAPM

- Tracking/ SVN, Redmine developments

Fields of expertise

- Analog electronic (Low/high power, high voltage, high temperature)

- Sensors

- Aeronautical, space and industrial ignition systems

- Emergency cockpit indicators (temperature, speed, torque)

Preliminary design

- Feasibility study

- Collaborative project

- R&T

Design

- Design to specification

- Maintenance in Operational Conditions

- Obsolescence management

Testing means: climatic chambers, vibration equipment, HALT chamber

CAD software (Solidworks, Cadence-Orcad)